The production process for ball bearings involves multiple precision manufacturing steps to ensure high-precision, high load capacity and long life. There are typical production processes and key technical steps as follows.

The production of ball bearings involves multiple precision-engineering steps to ensure high accuracy, load-bearing capacity, and long service life. Below is an overview of a typical manufacturing process and the key technical steps

1. Material Selection

Rings (inner and outer): Typically made from high-carbon chromium bearing steel (e.g., GCr15, GCr18Mo), stainless steel, or specialty ceramics.

Balls: Made from materials matching the rings, requiring high hardness, wear resistance, and fatigue strength.

Cage (retainer): Made from low-carbon steel, brass, nylon, or polyamide (PA66), depending on application requirements.

2. Material Inspection

Chemical composition analysis and metallographic examination ensure defect-free materials.

1. Turning

Rough Turning: CNC lathes are used to machine the outer/inner diameters and faces, leaving allowance for grinding.

Finish Turning: Grooves (raceways), chamfers, and other critical profiles are precisely machined to ensure geometric accuracy (e.g., roundness, concentricity).

2. Heat Treatment

Quenching: Heated to 840–860°C then oil-quenched to achieve 60–64 HRC hardness.

Tempering: Low-temperature tempering at 150–200°C relieves internal stress and improves toughness.

Cryogenic Treatment (Optional): Treated below -70°C to reduce retained austenite and improve dimensional stability.

3. Grinding

ID/OD Grinding: Centerless or CNC grinders are used to achieve IT5-grade dimensional accuracy.

Raceway Grinding: Dedicated groove grinders shape the raceway, achieving surface roughness Ra ≤ 0.2μm.

Superfinishing: Oilstones polish the raceway to Ra ≤ 0.05μm, improving stress distribution.

1. Forming

Cold Heading: Wire is cut and formed into rough spheres using multi-stage cold headers—high efficiency with over 90% material utilization.

Hot Forming (for larger balls): Balls are hot-rolled from heated materials.

2. Heat Treatment

Quenching and tempering process to achieve 62–66 HRC hardness, ensuring durability.

3. Precision Finishing

Hard Grinding: Brings the ball close to final size with roundness error ≤ 0.5μm.

Lapping: Balls are lapped against cast iron plates in multi-axis machines, achieving G10–G5 grade (±0.25μm diameter tolerance).

Polishing: Mechanical or chemical polishing reduces surface roughness to Ra ≤ 0.01μm.

1. Stamped Cages (Steel/Brass)

Sheets are stamped and stretched, followed by deburring and surface treatment (e.g., zinc plating, phosphating).

2. Molded Cages (Nylon/PA66)

Injection molded using precision molds, with tight control on shrinkage and dimensional stability.

3. Machined Cages (Large Bearings)

Brass rods are CNC turned to form pocket and lock structures.

1. Cleaning

Ultrasonic cleaning removes grinding residue, followed by drying and anti-rust treatment.

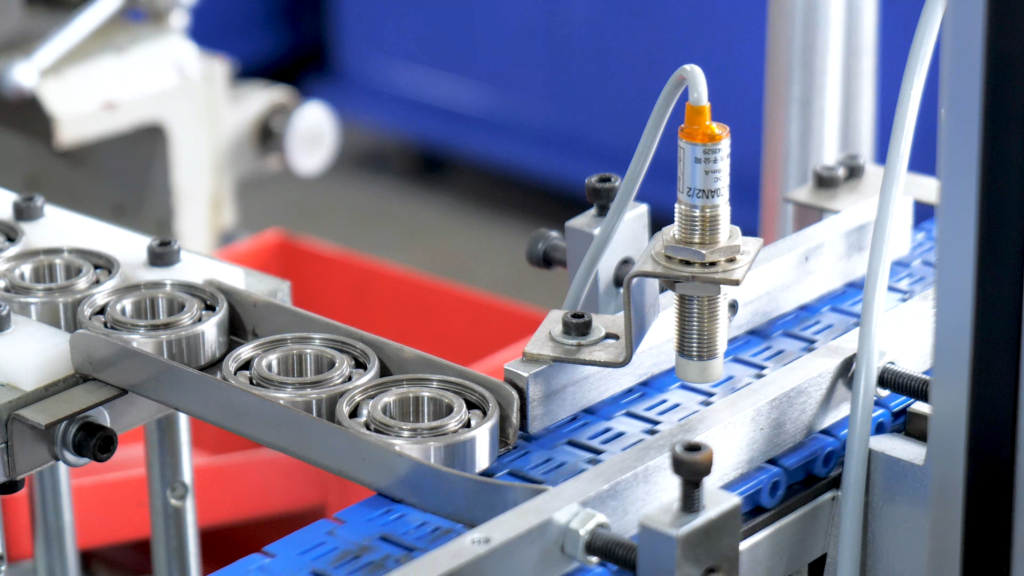

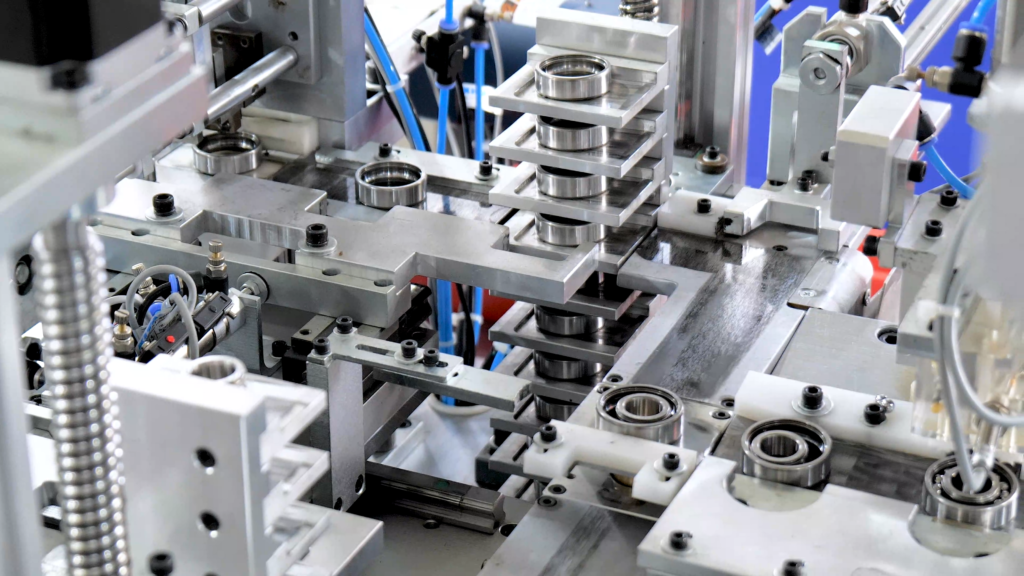

2. Assembly

Matching: Components are grouped by dimensions to ensure optimal fit between balls and raceways.

Ball Insertion: Balls are manually or robotically inserted and secured by the cage.

Riveting/Welding: Steel cages are riveted; nylon cages are heat-fused.

3. Lubrication

Lithium-based or synthetic grease is injected; some bearings are pre-coated with solid lubricants.

4. Final Inspection

Dimensional Checks: Radial and axial clearance, smooth rotation.

Performance Testing: Vibration levels (Z1–Z4), noise, and lifespan under simulated loads.

Non-destructive Testing: Magnetic particle inspection or X-ray to detect internal flaws.

Bearings are vacuum packed or coated with anti-rust oil to prevent corrosion during transit.

Environment Control: Stored in temperature- and humidity-controlled warehouses to prevent deformation.

Precision Control: Raceway profile error ≤ 2μm; ball diameter tolerance reaches submicron levels.

Cleanroom Standards: ISO 14644-1 Class 7 cleanroom environments prevent contamination and ensure long life.

Automation Trend: Widespread use of robotic handling, AI-based visual inspection, and digital traceability systems.

Thanks to this process, ball bearings can meet demanding application needs—from household appliances to aerospace technology.

sales@weilishun.cn

+86 181 2639 3085

B12-42, Tiangong Security Market, Niulanqian Industrial Building, Xinniu Road, Xinniu Community, Minzhi Street, Shenzhen, Guangdong, China

Copyright © 2025 Shenzhen Weilishun Technology Co., Ltd.